Understanding the Working of Hydraulic Tensioners

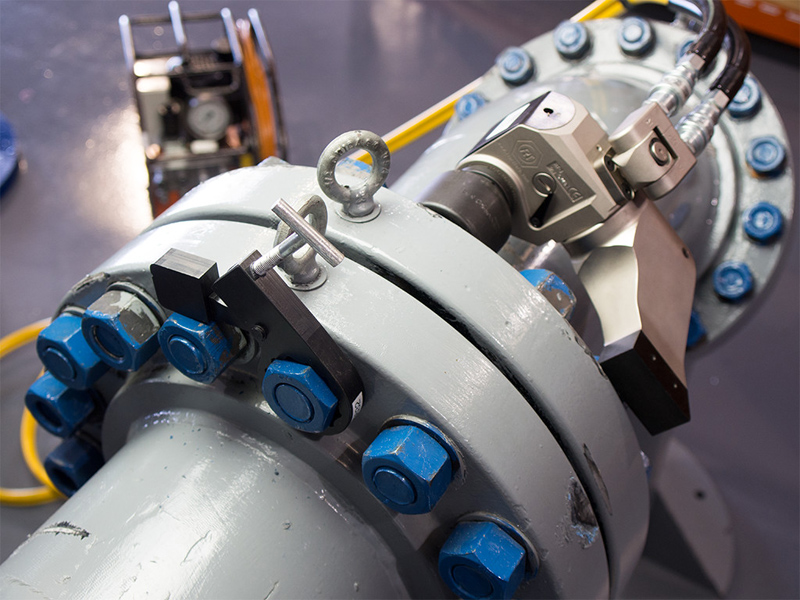

The general operating principle for Hydraulic Tensioners would be similar to all kinds of hydraulic tensioners and nuts models. There would be an axial and accurate load applied to the fastener applied by the high-pressure hydraulic oil. After the system reaches a predetermined pressure, the operator would make use of a small bar for making the nut run down by hand.

This has been highly complicated, as there has been no load on the nut. After the nut is seated by releasing the hydraulic pressure, the axial load would be transferred to the fastener. Among the several options, you would come across fixed, variable, and subsea hydraulic tensioner models. You would also come across hydraulic bolts and hydraulic nut.

Let us delve on the features and operation of hydraulic tensioner models.

Working of hydraulic tensioners

Find below the working of hydraulic tensioners.

- Compact hydraulic stud tensioners and fixed hydraulic tensioner model

The fixed hydraulic tensioner models have been simple, compact to use and highly economical. It would be pertinent to mention here that every tool has been adequately designed for single thread size. The Bridge would be placed over the nut by the operator along with the threads loading the Load Cell on the stud until it comes in touch with the bridge. The operator would be required to connect the hoses and follow the general operating steps.

- Flexible hydraulic stud tensioners and changeable hydraulic tensioner models

The changeable hydraulic tensioner models would enable the tensioning of numerous thread types or sizes of threads. It would use a single hydraulic load cell. The flexible hydraulic stud tensioner models would also entail hydraulic ports. It would provide them with the lowest installed height. The operator would place the Load Cell and Bridge over the nut. The operator would thread the separate puller bar on the stud until it comes in contact with the load cell. The operator would connect the hoses. He would be required to follow the general operating steps.

- Hydraulic nut

The hydraulic nut would replace the nut normally while using the stud and staying with it. This has been a most compact system and does not need additional stud length. The operator would be required to simply screw the hydraulic nut tight along with connecting the hydraulic hoses.

After you reach the pressure, the operator would either screw the collar down or look forward to inserting shims designed for the application.

Comments are closed.