Five Ways to Maintain the Optimal Functionality of your Centrifugal Pump

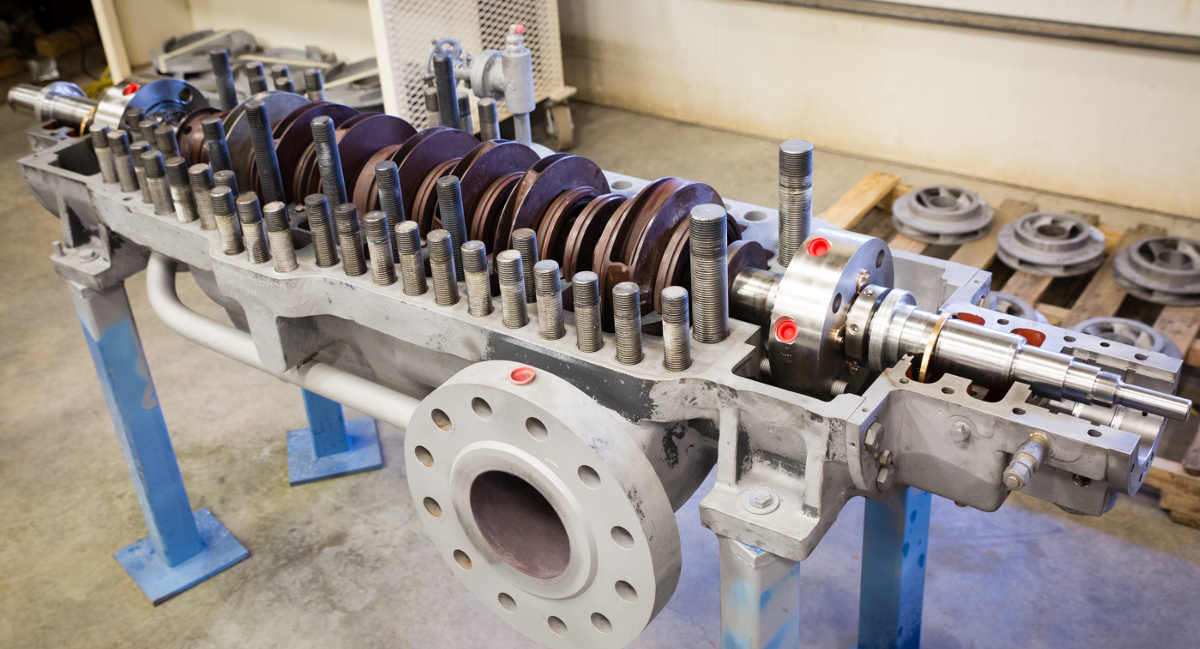

pumps are commonly used in both domestic and industrial settings like factories and plants. Although their design is likely to change, these pumps usually work at high velocity and pressure.

To make sure your sanitary pumps function optimally and last for the longest time possible, keep the following safety tips in mind:

Train your Employees Properly and Continuously

Before you let your employees work with a centrifugal pump, train them properly. All employees authorized to use the pump must know how and when to read pressure levels, handle the line draining procedure properly, and know how to use the emergency shutoff valve. Safety seminars must be held to teach your employees simple instructions like how to wear safety gear correctly. Make sure to update your employees when industry changes have been introduced to ensure compliance.

Emphasize the Risk of Overheating

Overheating the centrifugal pump can damage its internal components. Also, this kind of pumps can cause serious burns to workers who are servicing the pump. That is why you must emphasize to the authorized employees to avoid overheating the pump. The suction and discharge lines must be left open during operation. In case the pump overheats, it should be shut down and allowed to cool. Before starting the pump, the drain plug must be allowed to vent.

Replace Old Parts

Worn-out components of a centrifugal pump can result in workplace accidents and damage the device itself. Even small parts like bearing or casing wear ring can lead to catastrophic safety problems when they wear out. When the pump shaft begins to wobble, it can result in the pump overheating. You can avoid this concern by checking the safety suction lines and pipe plugs frequently. Over time, sealant can wear away and let foreign objects enter the pump itself. Worn out pumps and components must be replaced as often as possible.

Test the Pump for Air Leaks Regularly

When pump parts wear out and become old, they can experience air leaks. When there is air, the pump will often emit a loud, gravel-like noise. Ensure cavitation does not cause the noise by check the vacuum gauge reading. Erratic readings usually mean the suction flap valve, hose, or seals are worn out and must be replaced.

Understand when the Suction Could be Blocked

Centrifugal pumps can become blocked with foreign objects or mismatched parts. Sometimes, blockages can take place when the rubber lining in a suction hose pulls away from the fabric. Keeping the suction lines short and straight will eliminate vapor pockets or bubbles.

Comments are closed.